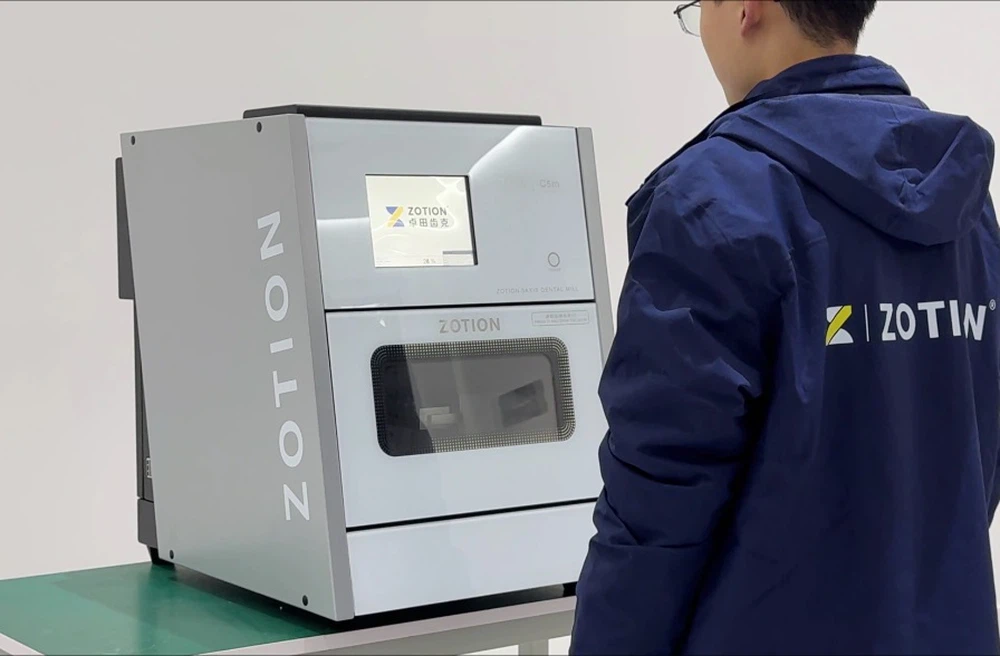

Dental Lab Equipment Titanium Premill Abutment 5 Axis Wet Milling Machine

Dental Lab Equipment Titanium Premill Abutment 5 Axis Wet Milling Machine is widely used in dental laboratories to make crowns, bridges, implant abutments, orthodontic appliances and other complex dental restorations. It has high precision and versatility and is one of the important members of dental laboratories.

Products Description

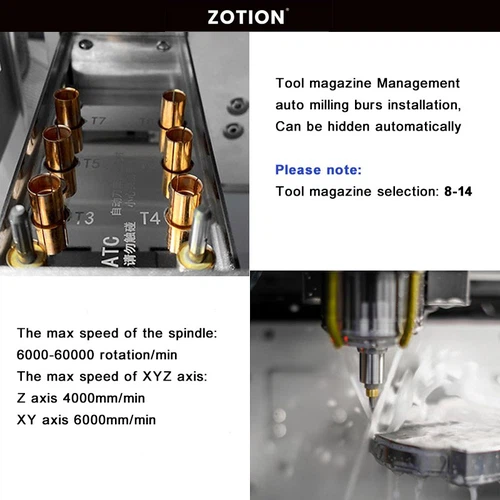

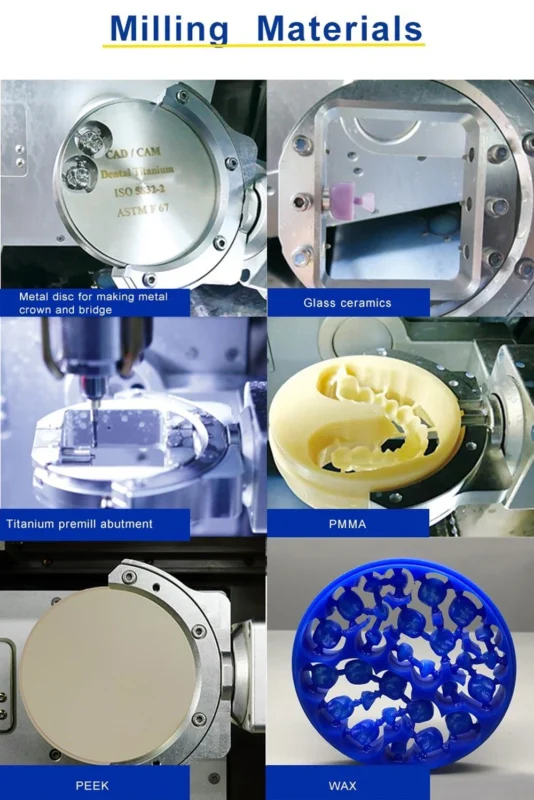

The Dental Lab Equipment Titanium Premill Abutment 5 Axis Wet Milling Machine can manufacture a variety of dental restorations (including crowns, bridges and abutments). The machine supports a wide range of milling materials, such as glass ceramics, titanium posts, titanium disks, PMMA and PEEK. The spindle operates in a speed range of 6000-60000 RPM, while the rotary axis provides +360° travel on the A-axis. Equipped with a tool magazine that can accommodate up to 14 tools with a shank diameter of 4×56 mm, it ensures flexibility in handling a variety of milling tasks. The machine has a rated power of approximately 650W and a maximum operating speed of 4000 mm/min on the Z axis and 6000 mm/min on the XY axis, allowing for efficient and precise milling. Its 5-axis milling technology with an accuracy of ±1° can provide high-precision results.

Products parameter

|

Tool magazine type |

Automatic |

|

Tool numbers |

14 |

|

Tool size |

Shank diameter 4*56 mm |

|

Control code |

NC code |

|

Program interface |

USB 2.0 ,100M network port |

|

Power requirement |

AC220v +-10%,50/60 Hz |

|

Power consumption |

650w |

|

Working decibel |

<45 decibels in standby:, < 70 decibels when running,The data was tested by UT353,the level of the noise varies when different materialis used |

|

Net Weight |

105 kg |

|

Size |

WLH 490mm*620mm*625mm |

Products Details

Products advantages

1. Useful fixtures for different materials

How it works: Multifunctional fixtures that can mill a variety of tool materials such as wax, glass ceramics, PMMA, composite resins and titanium. The fixtures are designed to quickly hold different types of materials in different shapes and sizes, ensuring stability during the milling process.

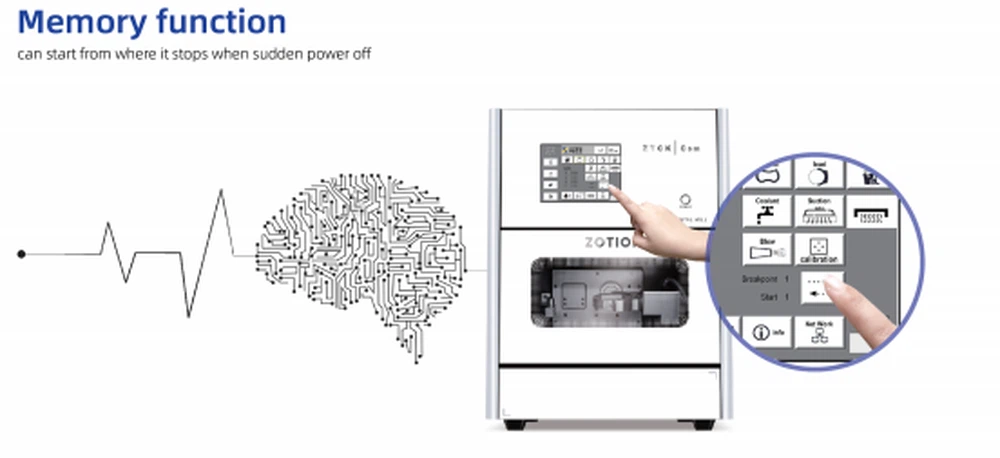

2. Memory function

How it works: The memory function allows the machine to save milling programs, settings and parameters for later use. Once a specific material or repair type has been processed, the settings can be stored in the machine system and called up when needed.

The memory function improves efficiency by reducing setup time. Technicians can load pre-setups for specific repairs, ensuring consistent results and reducing the possibility of errors caused by manual adjustments at each time.

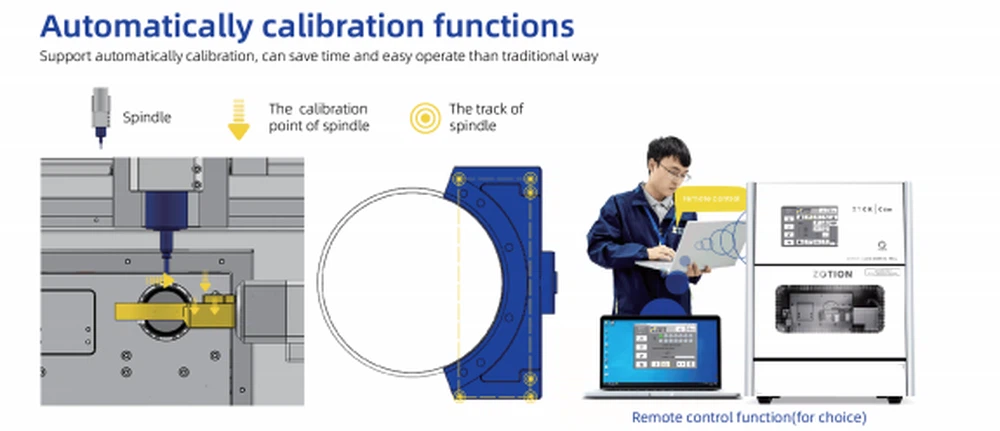

3. Automatic adjustment function

The machine is equipped with an automatic adjustment system that ensures the tilt of milling tools, slewing and fixtures. It automatically adjusts the machine’s working origin and corrects any tilt offset or deviation that may occur during the milling process.

Automatic planning improves accuracy and precision by maintaining the correct correction and reducing setup time.

If the machine detects a change in alignment due to thermal expansion or tool wear, it automatically readjusts to ensure the milling process remains accurate and stable, preventing repair errors.

4. Remote control function (optional)

How it works: The machine is equipped with a remote control function. Allows technicians to monitor and adjust settings, start or stop the milling process, and even troubleshoot from a distance. Fault remote control can be a convenient optional function.

The remote control function improves the convenience and flexibility of technicians.

5. Measuring head automatically corrects the work origin, large high-definition touch screen, simple operation

How it works: The machine is equipped with a high-precision measuring head that constantly monitors the position of the milling tool and automatically adjusts to maintain the correct origin during the milling process. The system can measure the position of the tool and adjust the movement accordingly to prevent any errors. The touch screen interface simplifies operation, reduces the learning curve, and enables more efficient, error-free work. Automatic correction of the work origin helps maintain accuracy.

Touch screen and adjust as needed.

6. 90° vertical machining of the restoration surface is possible

Vertical milling of the restoration surface at a 90° angle allows for precise milling of the top or functional surface of the restoration. The vertical machining capability ensures that complex geometries and fine details can be processed accurately without repositioning the workpiece.

90° vertical milling allows for more accurate cutting and finishing of the restoration fit and aesthetics.

Products certificates

Be the first to review “Dental Lab Equipment Titanium Premill Abutment 5 Axis Wet Milling Machine” Cancel reply

Related products

DENTAL PRODUCTS

CBCT & Panoramic X-Ray Units

Reviews

There are no reviews yet.