Economical Dental fast Sintering Furnace

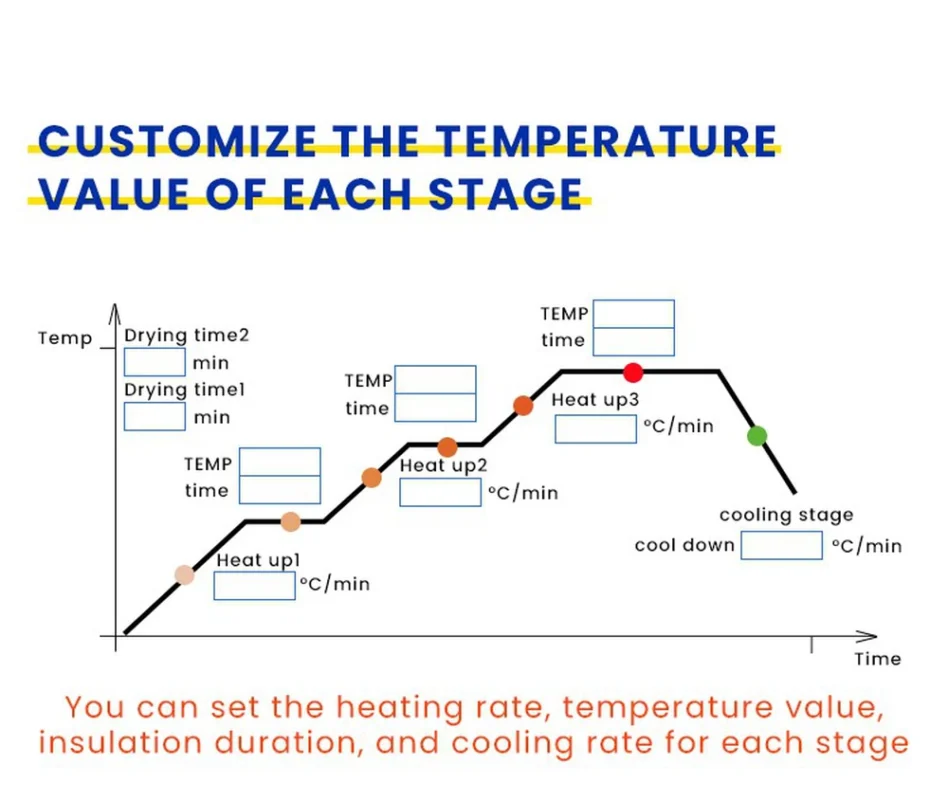

Zotion Economic dental Fast Sintering Furnace F2 consist of a double shell structure with excellent insulation. The specially designed structure ensures that the furnace can achieve fast heating and cooling procedures, providing a cleaner working environment during sintering process.It can sinter zirconia block, glass ceramics and glazing.F2 can be set up with multiple temperature profiles to meet the different sintering requirements of our customers. What’s more, Multiple languages for choice. The large size allows the furnace to sinter 3 crucibles (MAX.90 crowns) at a time,making it a good choice for dental labs and clinic. F2 are equipped with a touch screen control system for easier operation. Not only can sinter zirconia but also can sinter glass ceramics and glazing. It includes 20 sintering programs, the user can edit it ,so it is very friendly ,What’s more, the special design structure of the furnace allows for fast heating and fast cooling, It is very popular in the denture processing industry .It supports fast sintering and slow sintering both.

Reviews

There are no reviews yet.